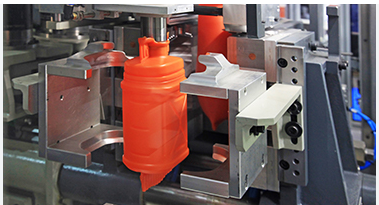

Rotomolding can be a much applied industrial action since it is really cost-effective. Its primary target would be to Rotational Molding product polymers, altering them into thermoplastics. The most common polymers are PVC, polyethylene, and polypropylene in this kind of process.

Numerous firms can create from the least complicated to really sophisticated components from the rotational molding process. Also, based on the purpose of the plastic-type materials, it really is a more prevalent alternative than alternatives for example blowing, shot, and vacuum method.

Rotational Molding is really a method that will allow the production of basic supplies along with a high level of complexness. These items are hollow and airtight, small, like a coin, or huge, like 25,000-liter tanks.

In this sort of part, the recurring challenges are generally tiny due to the shortage of strain about the resin. This procedure also manages producing inserts, threaded elements, gussets, double wall space, holes, and availabilities enabling components and colours to be easily substituted.

An entirely operated process

To accomplish superior quality components by using a well-managed approach, you need to have professionals. Granger Plastics Organization is the ideal companion for businesses that want the very best plastic materials products.

The equipment and molds employed in Plastics Rotomolding are generally less expensive than other molding procedures. This is certainly motivated by very low-charge materials such as nickel, aluminium, or metal. Furthermore, the parts manufactured by them usually do not require huge ultimate doing procedures.

One of the greatest benefits of this particular handling is rotomolding polyethylene can lead to more robust pieces with a decent shelf-life. Irrespective of how much this unprocessed fabric is used by around 90Per cent in the rotational molding marketplace in the world.

An entirely personalized service

Hardly any companies around the world provide the Rotational Molding assistance provided by Granger Plastics Organization since it supplies the last finishing service after Molding, storing of elements, and dispatching them to finish customers.